The guidelines at European level for

plastic industry players on sustainable packaging

At European level as well as worldwide, new legislations for sustainable packaging have been approved which monitor the amount of plastic packaging produced. Each company using a considerable amount of packaging need to have a sustainable packaging design strategy in place which aims at minimising the environmental impact from the packaging that they introduce into market.

The biggest trend for big companies is to join initiatives such as the ones developed by the Ellen McArthur Foundation (the New plastics economy) or the Alliance to end Plastic waste or Plastic Bank and signing pacts, therefore committing to reduce their impact coming from excessive plastic packaging.

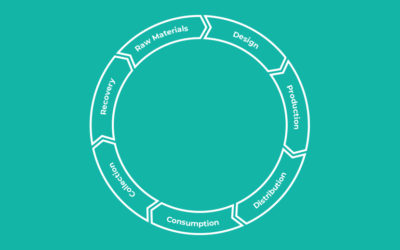

The Plastics Pact is a network of initiatives that bring together all key stakeholders at the national or regional level to implement solutions towards a circular economy for plastics. It connects initiatives and organisations from around the world, all working to implement a common vision for a plastics system that keeps plastics in the economy and out of the environment.

This movement has led to bigger governmental and regional bodies to put plastic strategies in place. One of these is the European Plastic Pact. This article describes the content of the European Plastics Pact. By signing this pact the players commit to actively set up cooperation with other value chain partners and report the results of such actions. All the members meet to share best practices keeping the network up to date. They also contribute to harmonise standards and guidelines in order to achieve a legislative framework matching the evolving industry status. You can find the content of the European Plastic Pact here.

The main goals that the participants work towards are the following:

Reusability and recyclability by design

- Design choices, product requirements and business models should promote reuse or recyclability without raising the total lifecycle environmental impact.

- Products, materials and technologies should reduce the complexity of sorting and recycling.

- No use of substances inhibiting recycling, among which substances of high concern for the environment and human health.

Responsible use of plastics

- Prioritise: (1) Reduction of unnecessary use of plastics; (2) Reuse systems; (3) Substitution of virgin plastics with recycled plastics or with materials other than plastics proven to be more sustainable.

- Investigate the feasibility and scalability of refill, deposit & return and other reuse models, including new business models and bringing these models into practice.

- Raise awareness and educate people about plastics reduction to achieve the desired changes in consumer behaviour.

- Aim to diminish the number of pieces of plastic waste found in the environment.

- Build a robust model for assessing sustainability and preventing substitution of plastics by less sustainable materials, using a complete life cycle and overall systems perspective.

Collection, sorting and recycling

- Provide consumers transparent tools and information on how to correctly dispose of plastic waste.

- Build an effective framework for separate collection and recycling of plastic waste.

- Develop optimum combinations of sorting, mechanical and chemical recycling technologies with the lowest possible environmental footprint for delivering the high-quality streams of materials required to be used in new products and packaging.

- Develop quality standards for sorting facilities to allow for best recycling.

- Develop clear output criteria for mechanical and chemical recycling.

- Incentive recycling by substantially reducing landfill and plastics waste export to countries outside Europe.

Use of recycled plastics

- Set up a system to ensure safe use of post-consumer recycled (PCR) plastics, in particular in food contact materials.

- Work together towards an average of at least 30% PCR plastics in new products and materials.

- Raise the capacity and quality of recycling to ensure adequate availability of high-quality PCR plastics.

- Investigate new incentives to promote the use of PCR plastics, e.g. incentives (eco-modulated fees) for producers which design their products to mitigate their impact on the environment.

- Develop demand-driven, credible quality standards for supply and demand of PCR plastics.

- Promote the use of sustainably produced and recyclable biobased plastics in addition to PCR, in order to reduce the use of virgin fossil-based plastics and CO2emissions.

Cyclic Design supports companies to reach the above targets by offering a range of services to develop and implement a sustainable packaging strategy.

Marilu is an award-winning designer, actively working in the circular economy field. She consults on sustainable product strategy and she designs innovative packaging solutions. Her experience combines a creative approach with the technical experience of packaging manufacturing and plastic recycling.

Enabling plastic packaging innovation for decreasing waste

Case study: which business models enable prevention of waste in the plastic packaging industry 1. The players involved in the plastic packaging value chain As you might be already aware, big brands, retailers and other stakeholders are increasing their...

How to design eco friendly packaging?

What to consider when designing eco friendly packaging, taking a lifecycle approach. Fruits have their own protective “packaging”. Lemons, oranges or other citrus fruits’ skin is rough, it protects from impacts, the round shape distributes forces evenly. Still, in our...

Four strategies to develop eco design products

What is the lifecycle of a product? For designers, aesthetics are definitively important to make people interested in using the product. However, the designer's role goes beyond that. In fact, the design of a product starts at the beginning of the product’s lifecycle,...