What to consider when designing eco friendly packaging, taking a lifecycle approach.

Fruits have their own protective “packaging”. Lemons, oranges or other citrus fruits’ skin is rough, it protects from impacts, the round shape distributes forces evenly. Still, in our supermarkets, we see such fruits individually wrapped in plastics.

The way we produce and consume plastic packaging is really getting out of hand. No wonder there are more and more regulations coming up to put pressure on the players that introduce plastic packaging in the market.

The European Parliament has set a ban on certain types of single use plastic items, such as straws, cutlery and cups. We hopefully will not see them around anymore by 2021!

In addition, each country is doing its part to take measures to reduce the amount of packaging generated by commercial activities or select more responsible suppliers. Germany, for example, has a new Packaging Act called VerpackG, enacted in January 2019. This law pushes companies that introduce packaging in the German market, to register as packaging producer, which entails paying a fee according to the amount of packaging generated or imported.

On the other side, initiatives like the New Plastics Economy by the Ellen McArthur Foundation is pushing the big market players to work towards the same vision of “eliminating the plastic items we don’t need; innovating so all plastic we do need is designed to be safely reused, recycled, or composted; and circulating everything we use to keep it in the economy and out of the environment.

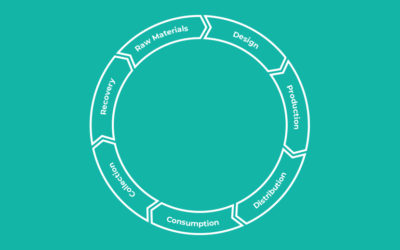

Following my design approach, based on lifecycle thinking, I will analyse the eco friendly packaging topic from a lifecycle point of view. At the same time, I will give guidelines on how to develop more sustainable packaging solutions by looking at the different phases of the packaging lifecycle:

1. Packaging production phase: a focus on material choice

Current packaging is made from fossil fuel, by a process called polymerization. Polymers are compounded with UV-stabilizers, anti-oxidants and/or other agents to obtain a plastic material with suitable properties for various applications. Virgin plastic is the resin produced from the petrochemicals, such as natural gas or crude oil.

Finding alternative materials to virgin plastics is the first consideration for the development of eco friendly packaging. The packaging material affects the energy consumption and the greenhouse gases emitted from the production process.

One might think directly about bioplastics as an alternative to petrochemical plastics. Bioplastics can indeed be a greener choice than virgin plastics, but not always. Among other reasons, they can create confusion when it comes to end-of-life. Bioplastics can be produced from different natural materials, for instance from starches (found in vegetables but also in organic waste, such as vegetables skin or coffee ground), casein (a natural phosphorus-containing protein found in milk), chitin (widely found in shellfish, insects and fungi), pectin (found in citrus fruits peels), but also from cellulose (contained in organic waste such as nuts shells). Even though the initial material remains better than virgin plastics, bioplastics are still a question mark when it comes to end-of-life.

Bioplastics can be treated as organic waste and processed in anaerobic digesters or in composting facilities. However, some some bioplastics can also be recycled exactly like virgin plastics. This causes confusion from the consumers’ point of view. Thus, guidance and clear information about how to dispose of such material is essential.

On the other side, introducing recycled content into the plastic blend is another option for reducing the environmental impact of plastic packaging during the production phase. The demand for Post Consumer Resin or PCR is increasing, which pushes packaging producers to interact more with recyclers. Some challenges around recycled plastics is reaching market standards of hygiene, as well as appearance qualities such as colours and textures.

2. Distribution phase: considering efficient transportation

As well as providing surface to showcase the brand message and information, the other key functionality of packaging is to reduce the risk of damaging during transportation.

Distribution includes transportation between the production facilities, for instance if the packaging is made with various components, the latter will be transported to the assembly point. Distribution also includes from the production site to the warehouse or the retailer. Let’s not forget that during transportation, an extra level of packaging is added in order to avoid any risks of damaging. These extra levels of packaging are called secondary packaging and transport packaging, they are an addition to the primary packaging. Usually secondary and transport packaging include carton boxes, internal carton partitions, any shock packaging as well as pellets and plastic film. They all must be considered when calculating the overall environmental impact of a packaged good.

When it comes to distribution, optimising the space occupancy is one of the strategies to implement for the development of more sustainable packaging. Reducing any empty spaces during transport of goods is not to be taken for granted. This can be achieved by designing modular packaging which can be stacked one on top of the other.

In addition, the overall weight of the products affects the amount of energy needed for transportation. Emissions from freight transport account for approximately one third of total transport GHG emissions. The heavier the goods transported; the more energy is needed to get moving. Therefore, avoiding the transportation of heavy items or materials decreases the impact from distribution.

3. Use phase: extending the packaging lifespan

The use phase of packaging relates to the period from when the packaging reaches the hand of the end-user until when it becomes waste.

During the use phase, the longer the user maintains the packaging, the later it will become waste. Most types of packaging sold today are disposable, having therefore a very short lifespan. Extending packaging’s lifespan is an important factor for minimising the impact from plastic waste. We would not therefore consume as much packaging in the same amount of time.

In response to this, reusable packaging is slowly entering the market as the alternative to disposable packaging. New business models to accommodate reusable packaging are being developed; new bulk stores are being opened, more durable packaging is produced, and incentive-based models are pushing citizen to join the movement.

Reusable groceries bags, reusable coffee cups are a just few examples. On a bigger scale, the Loop initiative is an example of how the re-usable packaging is becoming a bigger trend. Loop offers its reusable packaging with a deposit fee which will be returned to the consumer, once the packaging is returned.

New incentives need to be introduced for packaging producers to adopt a reusable model, instead of disposable. Currently, the more they produce the more they sell, their target is to produce as many units in the least amount of time. Getting producers on board with reusable packaging is harder challenge to overcome. Therefore, it might be faster when the demand for this solution comes from the consumer point of view. From the consumer perspective’s however, re-usable models need to meet convenience standards to be widely accepted by people. In fact, one of the biggest success factors of disposable packaging is convenience.

4. End-of-life: making recycling efficient

The end-of-life of packaging includes all activities that happening when the packaging is not usable anymore and becomes waste. Making post-consumer processes, such as recycling, easier or more efficient, would improve packaging’s end-of-life.

Packaging is used for various purposes, containing different types of content. To accommodate the various functions the packaging needs to perform, they are made with composite materials. This means that piece of plastic packaging, can include different types of plastics. Let’s take my favorite example, the shampoo bottle. A normal shampoo bottle is made with various component, the body of the bottle that need to be squeezed, the closure which open and close and the label. The body of the bottle is usually made with High Density PolyEthylene HDPE, which is a more flexible type of plastics which you can therefore squeeze. This component is usually produced using extrusion blow molding, a manufacturing technique that involves extruding a cylinder of warm plastic, which is then compressed between the two halves of a mold. A gas is then blown inside the expand the material to occupy the entire volume of the mold.

On the other side, the closure of the bottle is stiffer, and is usually made with PolyPropylene PP, a stiffer material, that enables the closure to open and close several times. The closure is produced using injection molding, a technique that enables a much higher level of shape complexity.

A strategy against the composite aspect of packaging, is producing mono-material packaging which do not need separation during recycling, decreasing the level of complexity during the recycling process. An example of this approach is my bottle design, Nepenthes, which combines the closure of the bottle and the body into one component (link). Nepenthes was recently awarded the KMU Innovativ Einstiegsmodul, which will enable us to advance in our R&D activities with the aim to bring the product to market.

- Replenish: http://www.myreplenish.com/

- Ecologic brands: https://ecologicbrands.com/

- MIWA: http://www.miwa.eu/

- Algramo: https://www.algramo.com/

- Cup Club: https://cupclub.com/

Four strategies to develop eco design products

Marilu is an award-winning designer, actively working in the circular economy

area. She consults on sustainale packaging and designs innovative packaging solutions. Her experience combines creative application with technical knowledge of packaging manufacturing and plastic recycling.

European Plastics Pact

The guidelines at European level for plastic industry players on sustainable packaging At European level as well as worldwide, new legislations for sustainable packaging have been approved which monitor the amount of plastic packaging produced. Each company using a...

Enabling plastic packaging innovation for decreasing waste

Case study: which business models enable prevention of waste in the plastic packaging industry 1. The players involved in the plastic packaging value chain As you might be already aware, big brands, retailers and other stakeholders are increasing their...

Four strategies to develop eco design products

What is the lifecycle of a product? For designers, aesthetics are definitively important to make people interested in using the product. However, the designer's role goes beyond that. In fact, the design of a product starts at the beginning of the product’s lifecycle,...